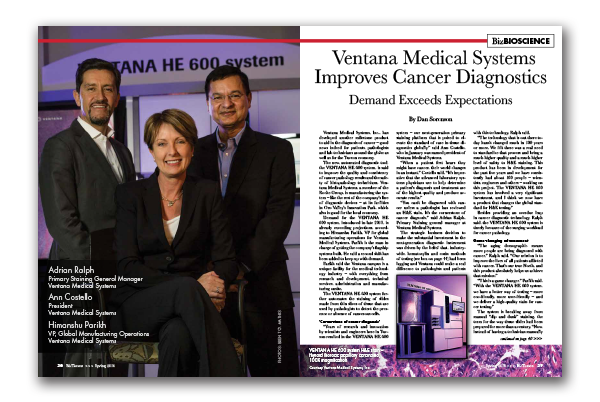

Ventana Medical Systems Improves Cancer Diagnostics

By Dan Sorenson –

Demand Exceeds Expectations

Ventana Medical Systems, Inc., has developed another milestone product to aid in the diagnosis of cancer – good news indeed for patients, pathologists and lab technicians around the globe as well as for the Tucson economy.

The new, automated diagnostic tool, the VENTANA HE 600 system, is said to improve the quality and consistency of cancer pathology results and the safety of histopathology technicians. Ventana Medical Systems, a member of the Roche Group, is manufacturing the system – like the rest of the company’s line of diagnostic devices – at its facilities in Oro Valley’s Innovation Park, which also is good for the local economy.

Demand for the VENTANA HE 600 system, introduced in late 2015, is already exceeding projections, according to Himanshu Parikh, VP for global manufacturing operations for Ventana Medical Systems. Parikh is the man in charge of getting the company’s flagship systems built. He said a second shift has been added to keep up with demand.

Parikh said the Ventana campus is a unique facility for the medical technology industry – with everything from research and development, technical services, administration and manufacturing onsite.

The VENTANA HE 600 system further automates the staining of slides made from thin slices of tissue that are used by pathologists to detect the presence or absence of cancerous cells.

‘Cornerstone of cancer diagnosis’

“Years of research and innovation by scientists and engineers here in Tucson resulted in the VENTANA HE 600 system – our next-generation primary staining platform that is poised to elevate the standard of care in tissue diagnostics globally,” said Ann Costello, who in January was named president of Ventana Medical Systems.

“When a patient first hears they might have cancer, their world changes in an instant,” Costello said. “It’s imperative that the advanced laboratory systems physicians use to help determine a patient’s diagnosis and treatment are of the highest quality and produce accurate results.”

“You can’t be diagnosed with cancer unless a pathologist has reviewed an H&E stain. It’s the cornerstone of cancer diagnosis,” said Adrian Ralph, Primary Staining general manager at Ventana Medical Systems.

The strategic business decision to make the substantial investment in the next-generation diagnostic instrument was driven by the belief that, industrywide, hematoxylin and eosin methods of testing (see box on page 44) had been lagging and Ventana could make a real difference to pathologists and patients with this technology, Ralph said.

“The technology that is out there today hasn’t changed much in 100 years or more. We felt there was a real need to standardize that process and bring a much higher quality and a much higher level of safety to H&E staining. This product has been in development for the past five years and we have consistently had about 100 people – scientists, engineers and others – working on this project. The VENTANA HE 600 system has involved a very significant investment, and I think we now have a product that changes the global standard for H&E testing.”

Besides providing an overdue leap in cancer diagnostic technology, Ralph said, the VENTANA HE 600 system is timely because of the surging workload for cancer pathology.

Game-changing advancement

“The aging demographic means more people are being diagnosed with cancer,” Ralph said. “Our mission is to improve the lives of all patients afflicted with cancer. That’s our true North, and this product absolutely helps us achieve that mission.”

“This is a game changer,” Parikh said. “With the VENTANA HE 600 system, we have a better way of testing – more eco-friendly, more user-friendly – and we deliver a high-quality stain for cancer testing.”

The system is breaking away from manual “dip and dunk” staining, the term for the way tissue slides had been prepared for more than a century. “Now, instead of having a technician manually prepare slides reusing chemicals, you have fresh chemicals automatically delivered onto each individual slide, creating a higher level of quality and standardization,” Parikh said.

Meeting the demands of cancer diagnosis

“Diagnosis is about the skill of the pathologist and his or her ability to interpret a stain,” Ralph said. “The tenets of the VENTANA HE 600 automated tissue diagnostic instrument were to make it easier and more reliable to provide a high level of standardization with reduced chance of misdiagnosis.

“What’s happening is that the number of patients presenting with cancer and the samples flowing through labs is increasing every year – but the number of technologists is not increasing. In fact, we have a shortage of pathologists and histotechnicians around the world. They’re being asked to do more with less,” Ralph said, which is why it made sense “to fully automate” H&E testing which today is still often manual or at best, semi-automated.

“The pathologist’s job is highly skilled and requires high levels of concentration to interpret the slide and make a diagnosis. Their workload increases every year, and we can help make their task easier with a crisper stain and high levels of reproducibility,” Ralph said.

The development team traveled worldwide to learn what pathologists in countries across the globe wanted in terms of H&E staining characteristics. Ralph said the responses were dramatically varied – from Australia’s preference for vivid colors, to pale, almost washed-out stain color preferences in China.

The Ventana team went back to the drawing board more than once, and the result was a product that allows pathologists to specify any of 400 different stain preferences.

Eliminates cross contamination

In the traditional H&E method, histopathology technicians fill up all their chemical and reagent tanks at the beginning of day, Ralph said. But as the day goes on, some cells may come loose from a piece of patient tissue on one slide and have the potential to cross-contaminate another patient’s tissue slide. When every sample gets fresh reagents through individual slide staining as achieved through the Ventana technology, the risk of cross contamination in the staining process is mitigated.

“Contamination can occur from one patient to the next,” Ralph said. “Sometimes it’s obvious, but it is quite common. In one study, ‘Tissue floaters and contaminants in the histology laboratory,’ 8 percent of slide samples showed contamination.

“At the very least, cross contamination slows down the pathologist’s diagnosis in the reading of the slide – or the pathologist sends it back for a re-slice of the tissue.”

And when a patient is waiting long hours and often days to learn whether they have cancer, that alone can be traumatic. Yet Ralph said, there is a possible outcome far worse than cross contamination.

“The very worst-case scenario is misdiagnosis resulting from cross-contamination,” Ralph said.

He cited a case in which a patient was diagnosed as having cancer in the mouth but the patient’s tissue sample was in fact cross-contaminated from another patient’s sample. The patient underwent a very invasive surgery based upon analysis of the contaminated slide. However, biopsy of tissue removed during the surgery found no sign of cancer.

Safer for histotechnologists

Parikh said with the VENTANA HE 600 system, there are potential health benefits for pathology labs and lab workers as well. “The output is much higher with less waste and no alcohol, no xylene.”

Xylene is an aromatic hydrocarbon traditionally used in H&E slide preparation, but is known to cause health problems with long-term exposure. Xylene figured into histopathology being rated as one of the jobs most hazardous to worker health. A 2013 Business Insider report ranked preparing H&E slides as the most dangerous of 974 occupations based on information about six health risks collected by the U.S. Department of Labor’s Occupational Information Network.

The VENTANA HE 600 also has implications for the future of cancer diagnostics. Though pathologists today typically work with the same lab day in and day out, Ralph said the future may very well involve more long-distance pathology work where experts might be making a diagnosis remotely – even in another country – from digital files of H&E slides sent to them electronically. That would require labs to generate a very clear and high-quality H&E stain that can be handled reliably by scanning technology.

Ralph said the VENTANA HE 600 system’s ability to provide consistency, then, becomes even more important.