Last Required Piece of World’s Largest Telescope Takes Shape at UArizona

The Richard F. Caris Mirror Laboratory will start fabrication of the seventh segment of the primary mirror necessary to complete the Giant Magellan Telescope. It marks a milestone in the search for other, potentially Earth-like planets and the exploration of the universe.

By Hannah Hindley, Steward Observatory

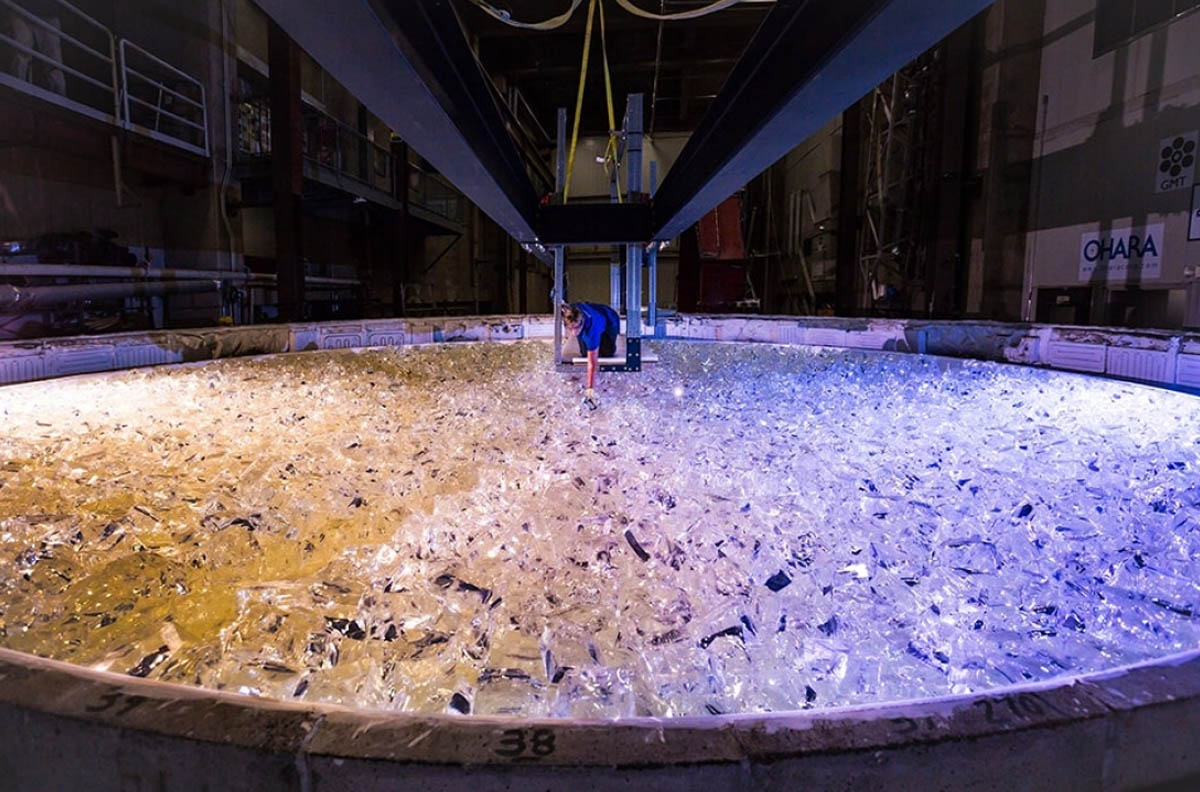

To make one of the world’s largest mirrors requires a lot of glass: 80 crates of it, to be exact – each containing 25 cases, safeguarded on double springs and distributed between the holds of four semitrucks.

On Sept. 11, this fleet of trucks parked outside Arizona Stadium, whose basement houses the UArizona’s Richard F. Caris Mirror Laboratory, and unloaded their glittering cargo. Forklifts trundled across polished cement floors, carrying 20 tons of gleaming borosilicate glass cubes, dense and clear as cut ice. Careful hands sorted the glass, discarding impurities, and loaded it into a rotating furnace 40 feet across.

Beginning on Oct. 6, technicians will heat the glass to 2129 degrees Fahrenheit – the temperature of flowing lava – and the furnace will begin to spin. It is the beginning of a four-year journey of meticulously engineered melting, casting and polishing that will result in a lightweight mirror nearly three stories high when stood on end. The mirror will then be shipped 5,000 miles to the Las Campanas Observatory in Chile’s high desert to become the final segment of the primary mirror required to complete the Giant Magellan Telescope, or GMT – the world’s largest telescope.

The scale of it all is enormous, but a primary intent of the GMT is to focus on things that are – cosmically speaking – quite small: tiny planets around nearby stars.

“You need exceptionally sensitive equipment to characterize Earth-like planets,” said Chris Impey, Distinguished Professor of Astronomy at UArizona’s Steward Observatory.

At 50 million times the power of the human eye, six times the light-gathering area of the largest telescopes in existence today, and 10 times the resolution of NASA’s Hubble Space Telescope, the GMT will give astronomers glimpses of the earliest distant stars and galaxies and will bring them the closest yet to finding life in the universe.

The mirror casting in October will be the culmination of over 40 years of research and development at the Mirror Lab. Research professor John Hill – who has witnessed every honeycomb casting in the lab since its inception – remembers returning to UArizona in his second year of graduate school in 1980 and meeting Regents Professor Roger Angel, who would go on to found the lab that same year.

“He showed me two Pyrex custard bowls that he’d fused together back-to-back in his garage, and he said we could make big telescope mirrors out of this technology,” Hill said.

Since then, the Mirror Lab, a unit of Steward Observatory, has become a world-leading laboratory for developing the technology and manufacturing techniques required to make the world’s most challenging large optics for telescopes.

Spin-casting is a unique process developed by Angel and his colleagues. Inside the spinning oven, a honeycomb-shaped mold will ensure the cast mirror blank will be mostly hollow, but with an internal structure like nature’s honeycombs, providing a lightweight support structure for the final surface of the mirror. As the glass on top of the mold heats and melts, it will ooze down and fill the gaps in the mold inside the oven. Pushed outward by the spinning oven, the molten glass will take on a curved paraboloid surface, close to the final shape needed for the telescope to focus the light from distant objects.

Over the next three months, the glass will be slowly cooled and the resulting cast mirror blank will be prepared for polishing. During the following four years, the surface of the mirror will be polished to the desired final shape with a surface accurate to a precision of 25 nanometers. The completed 8.4-meter mirror will be one of seven of the largest mirrors ever produced in the Mirror Lab – and the world.

The research at the Mirror Lab has been one of the many powerful drivers of Tucson’s identity as “Optics Valley,” a hub of high-revenue optics companies and astronomical observatories. The annual economic impact on the state of Arizona from the university’s space sciences research is the equivalent of hosting the Super Bowl – in part due to the optics coming out of the Mirror Lab.

The effort to develop the technology that enabled the GMT is a joint accomplishment of the Mirror Lab, Steward Observatory, the College of Science, Wyant College of Optical Sciences and the university. They have taken the innovations developed by Angel and his extended team to enable a telescope with unprecedented capabilities – and along the way they have attracted the funding to make this possible.

“Having all seven blanks cast is a major accomplishment that our Mirror Lab team should be very proud of reaching,” said Buell T. Jannuzi, director of Steward Observatory and head of the Department of Astronomy.

The scientists behind these innovations possess niche expertise that can be found nowhere else, according to Richard Wortley, casting manager at the Mirror Lab. Of the five-person casting team that he manages, Wortley said, “There are no other people in the entire world who can do what they do. They are the best I’ve ever worked with.”

For as long as it has existed, the lab has boasted a strong UArizona lineage. Many engineers have begun their time at the lab as graduate students or undergraduate employees, and have since stepped into leadership roles, including Wortley himself. Weaving together “a very peculiar mix of physics and engineering and art,” the Mirror Lab is a place where scientists often spend whole careers. “It’s a very close team,” Hill said.

The earthly scale of the GMT project is large: 13 partner institutions, nearly two decades of work since the first primary mirror segment casting for GMT, and ultimately a telescope in a building large enough to house a space shuttle.

The primary mirror of the GMT is made by grouping six circular primary mirror segments, each 27 feet in diameter, around a seventh mirror in the center, like petals of a flower. The resulting 82-foot-diameter primary mirror gives the GMT the resolving power and the ability to see fine detail, 10 times greater than NASA’s Hubble Space Telescope. The unprecedented sensitivity and resolution will allow astronomers to study exoplanets – like the nearest planet orbiting the star Proxima Centauri, four light-years away – and to look for biosignatures in the atmospheres of many planets. In the case of Proxima Centauri, the star’s planet is only 36 milliarcseconds from its sun – a hair’s breadth on the astronomical scale.

“There’s no telescope today that can resolve that small a separation,” said Laird Close, UArizona professor of astronomy and an expert in the development of the adaptive optics required to observe exoplanets. “That’s the incredible power of the GMT: We finally get access to habitable worlds.”

The GMT will also allow researchers to witness the formation of the first stars and galaxies, lending insight into where the ingredients of life came from. And in the search for such biomarkers, it may clarify the story of life on planets beyond the solar system.

“We really can start to answer the question of ‘Are we alone in the universe?'” Close said. “We might actually have a real answer in the next decade.’

Pictured above – University of Arizona Richard F. Caris Mirror Lab staff member placing chunks of Ohara E6 low expansion glass into a mold for casting primary mirror segment number five on October 2017. The process of manufacturing the final required segment will follow the same procedure. Damien Jemison, Giant Magellan Telescope – GMTO Corporation