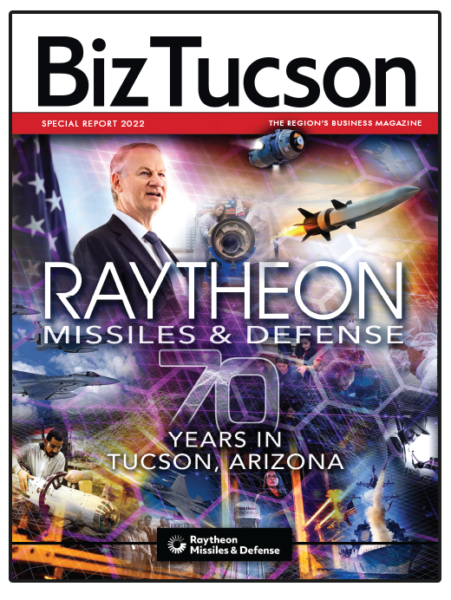

Raytheon Invests in New Capabilities, Partners with UArizona

Hypersonic Missiles

By Romi Carrell Wittman

Hypersonic technology, as it’s known, will revolutionize the defense industry and Raytheon Missiles & Defense is taking the lead.

But what exactly is hypersonic technology?

When Misty Holmes, Raytheon’s executive director of the hypersonic campaign, was asked to give a “‘hypersonic technology for dummies’ explanation,” she smiled. “That’s what I do all the time and enjoy most,” she said before explaining exactly what it is and how Raytheon is harnessing it.

Hypersonics are not really a thing. Hypersonic is an attribute…. a capability. What the U.S. is developing is a family of weapon systems that are air, surface and subsurface launched, to deliver a wide range of effects to the battlefield and allow defeat of targets that are threats to our country and our allies.

As the name implies, hypersonic means traveling at speeds greater than Mach 5, or five times the speed of sound. To put that into perspective, an aircraft traveling at Mach 5 would cross the Atlantic in roughly two hours, more than twice as fast as the fastest passenger plane, the Concorde. That’s a speed of around 3,800 miles per hour.

With hypersonic weapons time to target, flying greater than Mach 5, our adversaries have less time to react. These weapons also have an unpredictable flight path because they can maneuver, which makes them difficult to track.

Hypersonic technology has existed in the United States for decades. The Apollo spacecraft Gemini and Mercury reentered earth’s atmosphere at hypersonic speeds back in the early 1960s. Every space shuttle has moved at hypersonic speeds.

However, operationalizing this technology in the U.S. defense industry is a relatively new development. “The hypersonic threat from our adversaries is no longer science fiction. It is very real today and driving the need for accelerated capability,” Holmes said.

Under President Biden, the Department of Defense has increased funding for hypersonics research to $3.8 billion in FY22 to accelerate the development and testing of hypersonic weapons.

Holmes said it’s critical that Raytheon continue to support the USG to develop and manufacture this type of mission capability. “Our adversaries are visibly investing in and fielding hypersonic capabilities, and we need to do the same,” she said. “Rather, we must be competitive in battlefield dominance to maintain a strong deterrence posture to help keep our citizens and allies safe.”

Raytheon is developing two types of hypersonic missiles: Boost glide and ‘air-breathing’ missiles.

Boost glide hypersonic missiles are launched outside the atmosphere then glide down to their intended target. Rocket motors propel the missile, then the glide vehicle separates from the rocket and glides at extremely high speeds to reach its target. Boost glide capability requires exotic materials to address the heat challenge and offers longer range, maneuverability and shorter response times due to their extreme speeds

Air-breathing hypersonic missiles, on the other hand, achieve high speeds by a scramjet engine. The incredibly fast air flow through the engine propels the missile as opposed to the more complex rocket boost glide system. And unlike the boost glide, air breathers fly within the atmosphere generating a little less heat which means they can leverage more conventional materials, which lessens the cost to produce. Like boost glide systems, air breathers also maneuver and are difficult to persistently track.

The boost glide and air breather missiles are being developed primarily at the company’s Tucson facility, and remain in the demonstration phase. “We’re focused on building prototypes and increased testing frequency. We expect to see programs of record established within the DoD services in the next year,” Holmes said.

Building and testing hypersonic missiles is no small feat. One of the key challenges we face is making sure the materials that make up the missile can withstand the extremely high temperatures generated by an object flying greater than Mach 5. The materials science piece cannot be understated. Think of the heat shields necessary to protect the space shuttle upon reentry. This has been a major roadblock in the development of commercial hypersonic aircraft.

Then, testing must take place in several phases. First, the units are tested in a small-scale simulated environment, like the University of Arizona’s College of Engineering wind tunnels, where Gov. Doug Ducey recently toured along with Raytheon Missiles & Defense President Wesley D. Kremer.

Wind tunnels blow air at high speeds past stationary objects to better understand how objects will move in actual flight. Other testing must take place in a real flight environment and it is difficult to schedule range time. There are just a few capable ranges in the world that can accommodate hypersonic flight testing.

Thus, the road to manufacturing hypersonic missiles is a complex balance of material science, simulated flight testing and, finally, range testing to ensure the vehicle can fly the intended distance, maneuver as designed and withstand the extreme flying environment at hypersonic speeds. While Raytheon has competition in this segment primarily from Lockheed Martin, Northrop Grumman and Boeing, Holmes said Raytheon has an advantage with their decades of missile development and production experience, deep talent base, robust supply chain, and academic affiliations, like the one with UArizona.

“Our university has experience across the spectrum of hypersonics,” said UArizona College of Engineering Dean David Hahn. “At such high speed, we have good tools that allow us to simulate, and we also provide the capability with actual vehicles. We’ve figured out the materials that can withstand the heat. When something is moving that fast, huge challenges are presented.

Raytheon’s experience in digital engineering also provides an advantage. “We have the ability to show customers what to expect ahead of time,” Holmes said. Digital engineering has the added benefits reduced cycle time through more automation and manufacturing technology which results in faster production times and lower costs.

Holmes said Raytheon will be a leader in this space. “We have a lot of experience, and people look to us as the leader in being able to manufacture missiles at rate and deliver them to the warfighter.”

“Being able to have not only hypersonics capabilities, but being able to defend against hypersonic threats, is something that is not only important today, but is growing in importance every single day,” Kremer said, during his tour of UArizona’s wind tunnels. “Unlike many areas of science, where we have decades of experience, this is an area that’s truly emerging.