6. Mining & Surface Technology

By Christy Krueger

Mining has been a major industry contributor to Arizona’s economy and workforce for well over a century, and it helped our state earn The Copper State nickname in 1912.

According to the Arizona Mining Association, in 2018 the mining industry provided a statewide economic impact of approximately $6.5 billion and supported 38,963 jobs paying an average of $102,859.

In Southern Arizona alone, mines and mining-related businesses have been actively growing the industry for years, with some moving here more recently.

Freeport McMoRan, the largest publicly traded copper producer in the world, has been mining the Sierrita open-pit mine south of Tucson since acquiring the site from Phelps Dodge in 2007, the same year Arizona became the leading copper-producing state in the country.

ASARCO (American Smelting and Refining Company), which primarily mines copper, is based in Tucson. Its three largest open-pit mines are located in Pima and Pinal counties. ASARCO’s history goes back to 1888 when it was owned by a partnership that included William Rockefeller. It was then sold to the Guggenheim family in 1901.

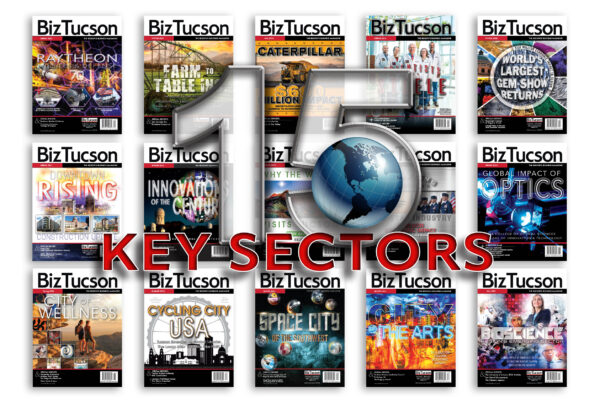

A true icon of American industry, Caterpillar saw the attraction of locating its Surface Mining & Technology Division to Tucson, opening its new facility west of Downtown Tucson in 2019. Prior to making the move, Tom Bluth, Caterpillar VP of the Surface Mining & Technology Division, talked with BizTucson about the company’s vision for the coming years here.

“We view this as a long-term decision,” Bluth said. He explained that having team members scattered around the country and in Europe felt “splintered,” and bringing them together in one location would create better synergy. “These different product groups would be able to share resources more and be able to work as a systems team. We also wanted to get them closer to mining and customers.”

Bluth admitted that one of the strongest things going for Tucson as a selection site was that Caterpillar already had a local presence with the Tucson Proving Grounds, where equipment is developed and tested. When Bluth spoke with Caterpillar’s local employees, their comments helped seal the deal. “They were very favorable to Tucson as a place to live. When I heard them say they prefer not to leave Tucson, that really helped me feel better about it.”

UArizona plays an important role in mining, having produced hundreds of graduates from the College of Engineering who are now working in the industry. In 2021, UArizona opened the School of Mining & Mineral Resources, which focuses on sustainability in the industry. And Pima Community College contributes to the workforce through its courses in mining technology, an area that is growing throughout the world.

The availability of a locally trained workforce is one branch on the mining tree that helps draw large corporations to the region. Hexagon’s Mining division, which concentrates on mining technology, established its world headquarters in Tucson in 2018. “We run a global mining division out of Tucson with about 1,300 people worldwide,” noted Hexagon divisional president Nick Hare. “Our solutions cover every step in the life of a mine from design and planning, to extraction, haulage and safety at mines.”

“We need the University of Arizona’s Eller College of Management in addition to their mining and engineering schools,” Hare said. “The expertise transmitted to their students is really important. In fact, Hexagon worked with UArizona to build a class called Mining 4E. We use it for onboarding new engineers and knowledge-building for non-specialist roles where understanding industry basics is a plus. We certainly benefit from being an economic and education hub.”

The trends in mining technology now, he said, are automation, safety and sustainability. “It’s like we’re taking multi-ton haul trucks and turning them into Teslas, being able to run and navigate them in a safe and sustainable way. Tucson is interesting for the development of these technologies because of the proximity of equipment providers and mines like Caterpillar, Komatsu and TuSimple. And Freeport and Magma Copper mines are nearby.”

Hare stressed the importance of safety and worker health. “Mining can be very dangerous and that’s where our Collision Avoidance Systems, Personal Alert and Operator Alertness Systems are part of technology. We can intervene with a vehicle, we can control it and hard-stop it if we see a possible collision.”

Hexagon and the mining industry in general are also focusing on the carbon footprint and the return on their investment. “Many companies are now dictating safety,” said Hare, “but also the carbon footprint.”

The reasons for Hexagon’s loyalty to Tucson are numerous, including the proximity to mines and customers, the weather, good education and accessibility of airports in Tucson and Phoenix. “Mining is a critical industry for the world,” Hare said. “We need these commodities and resources, and extracting and moving them in the most efficient, safe ways for people and the planet is foundational.”